RCO Security is a Swedish company established in 1976. Today, they have approximately 50 employees and are market leaders in products and systems for electronic and keyless locks. They deliver products such as code locks, electromechanical locks, and access control systems. Other product types include integrated alarm systems and intercoms.

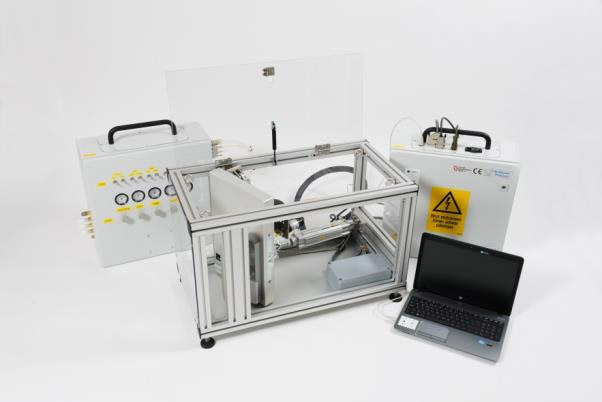

When RCO wanted to develop a new electric motor driven locking cylinder, Svekon were given the task of carrying out a preliminary study in order to create a proposal for a technical solution. The assignment was extended and developed further into a new product family of readers for cable-less installation, called NoKey.

This assignment came to comprise everything from studies to the start-up of production. Several prototypes were developed during the process, including freeform prototypes, which were produced using SLS and SLA technology. Production tools were also developed.